Find out how Christmas artificial firs are produced, the materials used and why they can be a sustainable choice.

Finally, it’s time! The most magical time of the year has arrived, Christmas Day is getting closer and closer. It’s time to take the decorations out of the boxes and decorate the house! Where to start? Obviously from the tree, which will keep you company in the living room throughout December (and maybe even until Easter if you forget to put it in its place again this year!). As you search for instructions on how to assemble it, you may find yourself thinking: how does artificial Christmas trees go about production? What material are artificial firs made of? Are they harmful to the environment? In fact, these are frequently asked questions and certain doubts arise spontaneously when you notice all that plastic… In reality, synthetic trees are an excellent alternative to natural ones and their production is really very interesting!

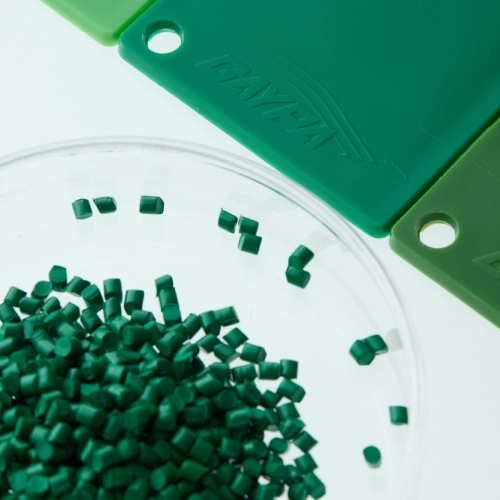

Artificial fir production: the role of masterbatches

First of all, we must make a distinction: there are two main methods for making the branches of artificial fir trees. One method employs the plastic extrusion process, the second injection. In both cases, the chosen polymer resin (usually PVC or PE) is added with pigment-laden masterbatches which, once mixed with the plastic, give the typical color to the trees, usually green and brown. In addition to the coloring pigments, it is also possible to add additional additives to the masterbatch formula that will give the final result unique characteristics. For example, an anti-UV additive for outdoor artificial fir trees will give the material greater resistance to sun exposure, ensuring color durability. Or, flame retardants or antimicrobial additives can be an additional guarantee of safety for domestic environments. An anti-static additive could help counteract dust build-up.

Christmas tree production: extrusion method

As we said, there are two main methods for producing artificial Christmas trees. The most popular is the extrusion method, a process similar to that used to create synthetic turf. The process begins with a PVC compound that is heated and extruded into continuous sheets, forming a large coil-like skein. This roll is then cut into long, thin strips. Then, these strips are transported in a machine that has the task of cutting them by making small incisions only on the edges of one side, simulating fir needles. At this point, the carved PVC strips are twisted together with wire that gives shape and rigidity and the piece thus assembled is cut to the desired length. This method makes artificial fir trees from branches with “soft” needles, similar to fettuccine, practical and durable, but less close to a natural effect.

Christmas tree production: injection method

The second method of making artificial fir trees is injection, which gives a shape more similar to both the eyes and the touch to a real tree. The processing, however, is more complex and, consequently, the price will also tend to be higher. In this case, PE (polyethylene) is used as a resin. Once a compound has been created with masterbatches and/or pigments and additives, the plastic is brought to a high temperature, up to the melting point. Here it is injected into molds that exactly reproduce the shape of pine needles. Once cooled, the branches are harvested and assembled using the wire, after careful quality control. To optimize production costs and ensure a good aesthetic result, PVC and PE branches are often combined. The former are inserted internally to create a tree filling effect, while the latter are placed outside to give a more pleasant and natural sensation to the eye.

Other characteristics of artificial fir trees

At this point, the branches are ready to be joined to the central structure. The most common artificial firs on the market have a hook interlocking system of branches, in which they are “set” directly on the trunk in special slots. There are also trees with umbrella openings and those already pre-assembled, for which it is sufficient to lower and open the branches. The other parts that make up the synthetic tree are the pedestal, or the support structure, usually made of metal, and the central structure, i.e. the trunk of the tree, which can also be made of a metal bar, or a PVC plastic tube pigmented green or brown. In addition to this, the tree can be completed with the addition of lights, or a splash of fake snow, made with synthetic fiber spray.

Are artificial firs a sustainable choice?

To answer the question: is the production of artificial Christmas trees sustainable? It has been found that artificial firs are a valid substitute for real firs, even if they are made from non-biodegradable plastics. In fact, a synthetic Christmas tree can be used for over ten years (if you stop to think, 10 Christmases is not a lot!). For this reason, it is a more sustainable choice than cutting down live plants or uprooting trees to be planted in pots, out of their natural habitat. Among other things, many companies producing artificial Christmas trees, driven by current market needs, are opting for the production of fir trees in recycled and bio-based plastic. Therefore, if chosen and used for a long time, a Christmas artificial fir tree can be a valid solution to help preserve natural resources.

Color your holidays with us and all year round!

Learn more about the world of masterbatches. Get to know our company and how we can make your world more magical and colorful, 365 days a year!